Project Summary

The FETT project (full title Novel manufacturing methods for Functional Electronic TexTiles) is a collaboration between the University of Southampton, Nottingham Trent University and 10 commercial partners (see below). It is concerned with the research and development of new assembly methods that add electronic functionality to textiles.This 4 year project is funded by the EPSRC under the Manufacturing Advanced Functional Material call.

Textiles are ubiquitous and are used, for example, in clothing, home furnishings as well as medical, automotive and aerospace applications, but their functionality is typically limited to their appearance and physical properties. There is considerable and growing interest in electronics textiles (e-Textiles) that add electronic functionality to textiles. e-Textiles offer a far greater range of functionality that can include sensing, data processing and interaction with the user and, as a result, can be applied in a vast range of applications potentially wherever textiles are present. The potential for the technology is enormous and the ability to reliably incorporate electronics in textiles will transform the textile industry.

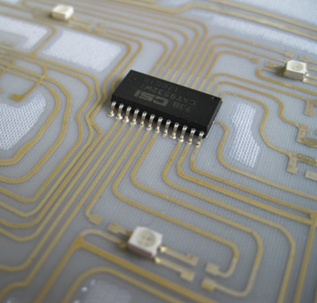

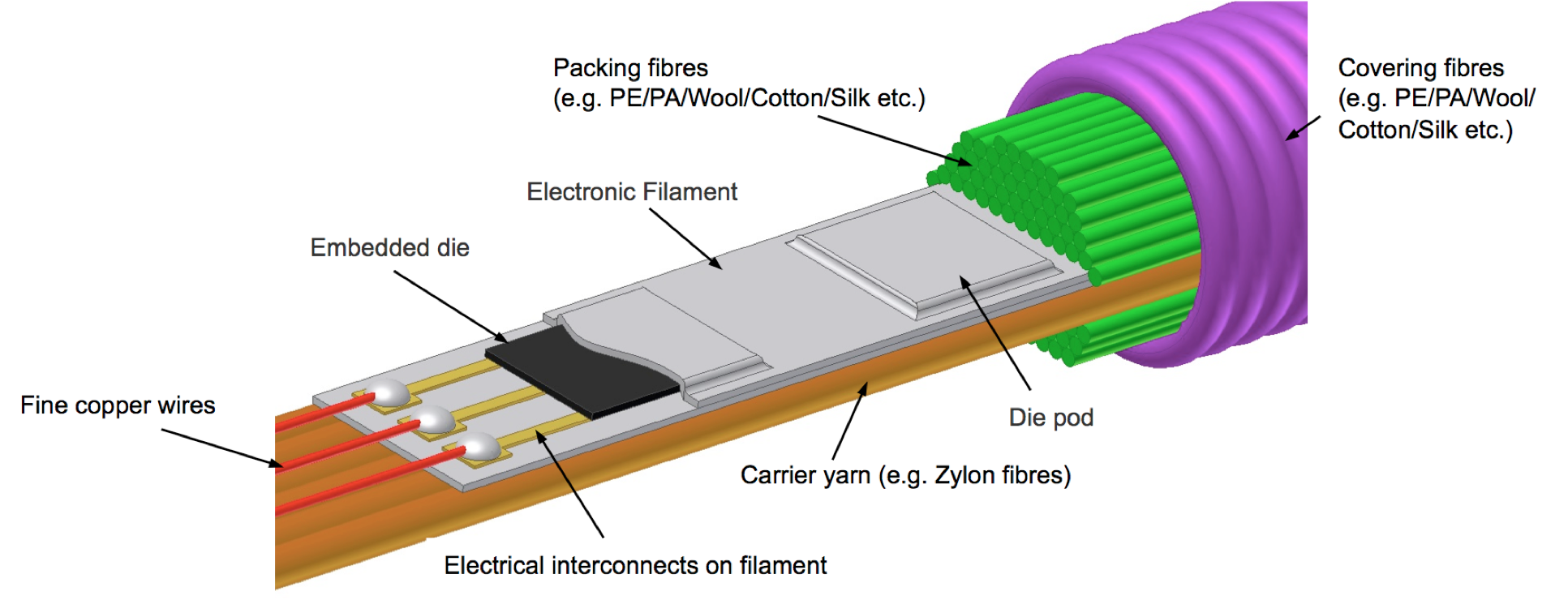

The overall objective of the research is to develop new manufacturing assembly methods that enable the reliable packaging of advanced electronic components (e.g. microcontrollers, sensors) in ultra-thin die form within a textile yarn. The programme of research will investigate approaches for mounting the ultra-thin die onto thin flexible polymer films strips that contain patterned conductive interconnects and bond pads. Individual die will be located on the strip and encapsulated to form a die pod and conductive tracks on the plastic substrate will link the die pods together forming a long, very thin, flexible circuit or electronic filament. The figure below shows one end of the yarn with the fibres cut away to show the filament that extends further into the yarn and contains numerous die pods.

Key Project Facts

- EPSRC funded ( ref EP/M015149/1)

- Start date 1st March 2015

- 48 month duration

- Full project budget £2.81 M

- Project led by Prof Steve Beeby (Southampton) and Prof Tilak Dias (NTU)

Partners

The project collaborators cover the manufacturing supply chain and end users of the technology and who are ideally positioned to capitalise from the outcomes of the research. End users include International Automotive Components Group Ltd (specialise in car interiors); Stretchline (UK) Ltd (manufacturer of narrow woven, knitted elastic and rigids); BSN Medical Ltd, Medicity, Royal Centre for Defence Medicine and URGO (medical products e.g. wound care); Speedo (swimwear); Dstl (security applications). Technology collaborators include Plessey Semiconductors Ltd (UK manufacturer of semiconductor products) and the TSB high value manufacturing catapult Centre for Process Innovation (CPI).

These collaborators form the industrial advisory board that will ensure the research is commercially and industrially relevant and that high volume manufacturing will be considered from the outset. The collaborators will inform the direction of the research by, for example, specifying the requirements for the demonstrators. This will ensure a deeper appreciation of the requirements and capabilities of all parties and ensure a two-way flow of knowledge and expertise.

Dissemination

The outputs from this project will benefit a range of industries and disseminating results using wide range of engagement activities is a key objective of FETT. This will include fashion trade shows, smart fabrics and wearable technologies events that reach a very wide audience across many disciplines. We will also engage with the flexible electronics community through the Plastic Electronics conference series which includes a wearable electronics theme. We will also organise a one-day workshop and invite participants from across the supply chain, end users and academic researchers. The research will also be communicated through Journal publications and conference proceedings

This research topic is also something that the general public can easily relate to and therefore wider outreach activities will be targeted towards the end of the project. These activities will include participation in Science festivals across the UK. We will also publish non-technical articles and issue press releases at certain key milestones.

Contact Us

Please Contact

Prof. Steve Beeby

email: spb@ecs.soton.ac.uk

tel: 023 8059 6663

Prof. Tilak Dias

email: tilak.dias@ntu.ac.uk

tel: 0115 848 6518